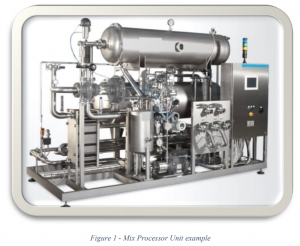

Mix Processor

Meter-based mix processors designed to produce carbonated beverages metering syrup, deaerated water and CO2. The mix product is cooled by a plate heat exchanger with glycol or ammonia. Finished mix product can also bypass the blender portion of the mix processor and be chilled and carbonated. Instruments, automatic valves and controls…

Flash Pasteurizers

Flash pasteurizer units are designed to eliminate microorganisms and enzymes to preserve product characteristics…

Tunnel Pasteurizers

The tunnel units are designed to ensure suitable thermal treatment to products of various sizes and package types…

Deaeration Systems

Deaeration Systems

Carbo Coolers

Carbo Coolers

Carbo Mix

Carbo Mix